Product Description

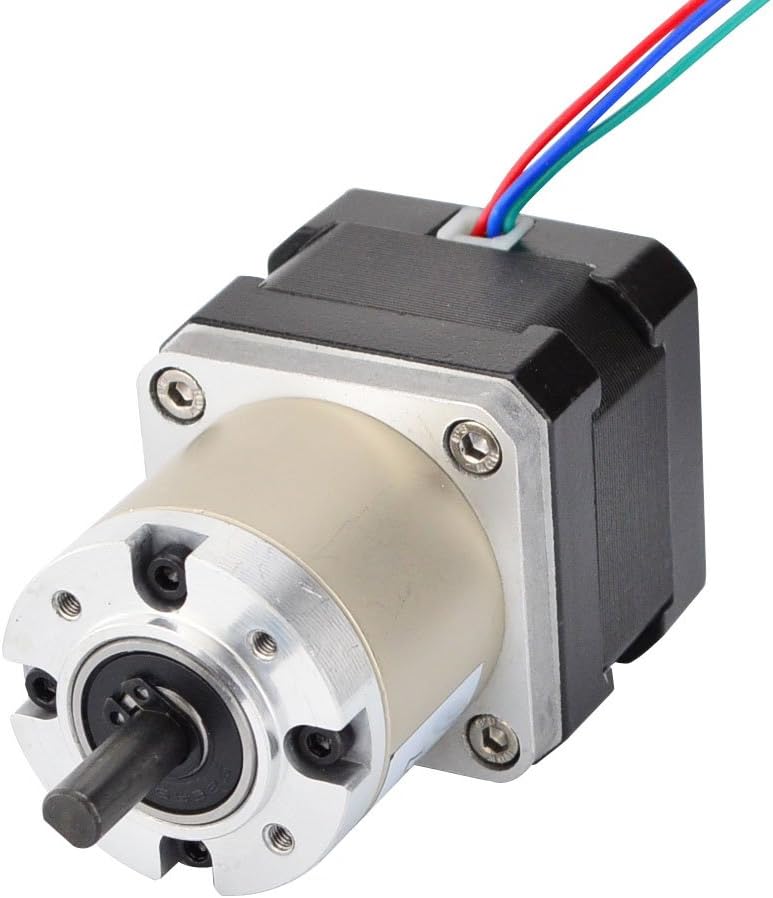

Good Quality High Torque PAD Series Planetary Gearbox Speed Geared Reducer with Square Flange Output

PAD sereis flange output planetary reducer features compact structure and high precision. Compared with other general gearbox, the use of PAD enables the installation space to be saved. The compact structure performs high torsional rigidity, and the taper roller bearing support provides high axial and moment load capacity.

PAD planetary gearbox is suitable for motion transmission where high positioning precision is required, and other automatic fields like dynamic cyclic operations, CNC machines and robotic industry.

– Precision Grade:

P0 ( ≤ 1 arcmin, ≤ 3 arcmin )

P1 ( ≤ 3 arcmin, ≤ 5 arcmin )

P2 ( ≤ 6 arcmin, ≤ 8 arcmin )

– Service Life: 22000h

– Operating Temperature: -15ºC ~ +90ºC

– Protection Grade: IP65

– Mounting Position: Any Direction

– Efficiency: ≥ 94% ~ ≥ 97%

Product Parameters

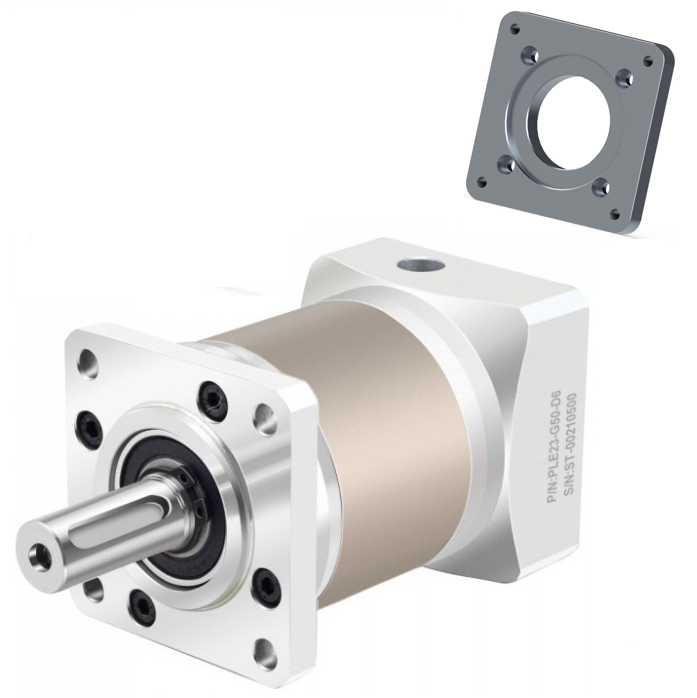

Detailed Photos

14 types of speed building ratio:=4-100

Minimum return interval: P0, P1P2

Maximum output torque: 23N. m-650N. m

Extremely high torsional rigidity and excellent performance

The highest load free policy is used in conditions with extremely high bearing capacity

Optimize power transmission and increase efficiency line by 98%

Very quiet during operation

Lifetime lubrication, no push protection

Fully sealed, IP65 protection level

Shortest structure and flexible installation

Small model: 64.90.110.140

Application

Product Description

Precision planetary gear reducer is another name for planetary gear reducer in the industry. Its main transmission structure is planetary gear, sun gear and inner gear ring.

Compared with other gear reducers, precision planetary gear reducers have the characteristics of high rigidity, high precision (single stage can achieve less than 1 point), high transmission efficiency (single stage can achieve 97% – 98%), high torque/volume ratio, lifelong maintenance-free, etc. Most of them are installed on stepper motor and servo motor to reduce speed, improve torque and match inertia.

Company Profile

Certifications

Packaging & Shipping

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

Calculating Torque Requirements for a NEMA Gearbox

To calculate torque requirements for a NEMA gearbox, you need to consider factors like load type, speed, and efficiency. Use the formula: Torque (Nm) = (Power (W) × 1000) / (Speed (RPM) × Efficiency). Determine the required power and speed, and account for efficiency losses. Ensure that the calculated torque is within the gearbox’s rated torque capacity. It’s essential to factor in safety margins and dynamic loads for accurate results.

Lubrication for NEMA Gearbox

NEMA gearboxes require proper lubrication to ensure smooth operation and longevity. It’s recommended to use the lubricant specified by the manufacturer, typically a high-quality industrial gear oil. Properly fill the gearbox with the recommended lubricant, ensuring it reaches the correct level as indicated by the manufacturer. Regularly check and maintain the lubrication level according to the manufacturer’s guidelines to prevent overheating and wear.

Key Features of NEMA Gearboxes

NEMA gearboxes feature a standardized mounting interface that ensures compatibility with NEMA motors. They are designed to provide efficient power transmission, torque multiplication, and speed reduction. These gearboxes are constructed from durable materials, such as cast iron or aluminum, to withstand varying loads and conditions. They often include precision-machined gears for smooth operation and reduced noise. NEMA gearboxes come in various gear ratios to accommodate different speed and torque requirements. They also offer options for different mounting orientations and motor flange sizes. These features collectively make NEMA gearboxes versatile and suitable for a wide range of industrial applications.

editor by CX 2024-03-10

by

Tags:

Leave a Reply