Product Description

assembly reduction gear reducer motor drive wheel right angle stainless steel self locking helical application small nema winch worm gearbox manufacturer

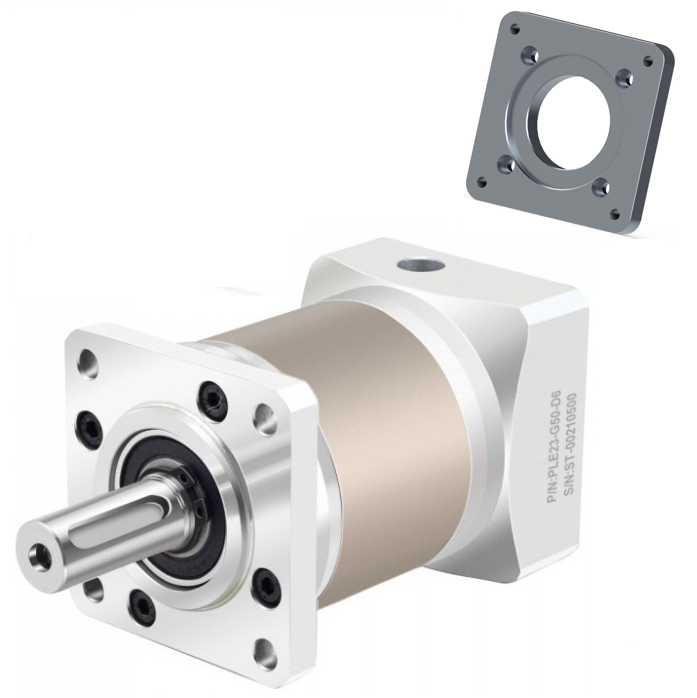

worm gearbox

A worm gearbox is a type of mechanical transmission that uses a worm gear and a worm wheel to transmit power. The worm gear is a screw-shaped gear that meshes with the worm wheel, which is a gear with teeth that are cut perpendicular to the axis of rotation. The worm gear rotates the worm wheel, which in turn rotates the output shaft.

Worm gearboxes are used in a wide variety of applications, including:

- Machine tools: Worm gearboxes are used in machine tools to provide smooth and controlled movement.

- Robotics: Worm gearboxes are used in robotics to provide precise and controlled movement.

- Medical devices: Worm gearboxes are used in medical devices to provide smooth and quiet operation.

- Other: Worm gearboxes are also used in a variety of other applications, such as food processing, material handling, and packaging.

Worm gearboxes offer a number of advantages, including:

- High torque: Worm gearboxes can transmit high torque, which makes them ideal for applications that require a lot of force, such as lifting heavy objects or driving machinery.

- Low speed: Worm gearboxes can reduce the speed of a rotating shaft, which can be useful for applications that require a smooth and controlled movement, such as in robotics or medical devices.

- Efficiency: Worm gearboxes can be efficient, converting up to 90% of the input power into output power.

- Durability: Worm gearboxes can be durable and have a long lifespan.

- Cost-effectiveness: Worm gearboxes can be a cost-effective way to improve the performance and durability of a system.

However, worm gearboxes also have some disadvantages, including:

- Noise: Worm gearboxes can be noisy, especially at high speeds.

- Vibration: Worm gearboxes can vibrate, especially at high speeds.

- Cost: Worm gearboxes can be more expensive than other types of gearboxes.

Overall, worm gearboxes are a versatile and reliable component that can be used in a wide variety of applications. They offer a number of advantages, including high torque, low speed, efficiency, durability, and cost-effectiveness. However, they also have some disadvantages, such as noise and vibration.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Troubleshooting Abnormal Noises in a NEMA Gearbox

If you encounter abnormal noises in a NEMA gearbox, first check for proper lubrication, inspect for damaged or worn components, listen for specific sounds like grinding or clicking to identify potential issues, ensure proper alignment and mounting, and refer to the manufacturer’s troubleshooting guide. If the issue persists, consult a professional technician to diagnose and address the problem.

Maintaining and Servicing a NEMA Gearbox

Maintaining and servicing a NEMA gearbox involves regular inspections, proper lubrication, and addressing any issues promptly. Follow the manufacturer’s maintenance schedule and guidelines. Keep the gearbox clean and free from debris, and check for any leaks or unusual noises. Lubricate according to specifications with the recommended lubricant. Replace worn or damaged parts, such as seals or bearings, as needed. Regularly monitor temperature and vibration levels. Proper maintenance can prolong the gearbox’s life and prevent costly breakdowns.

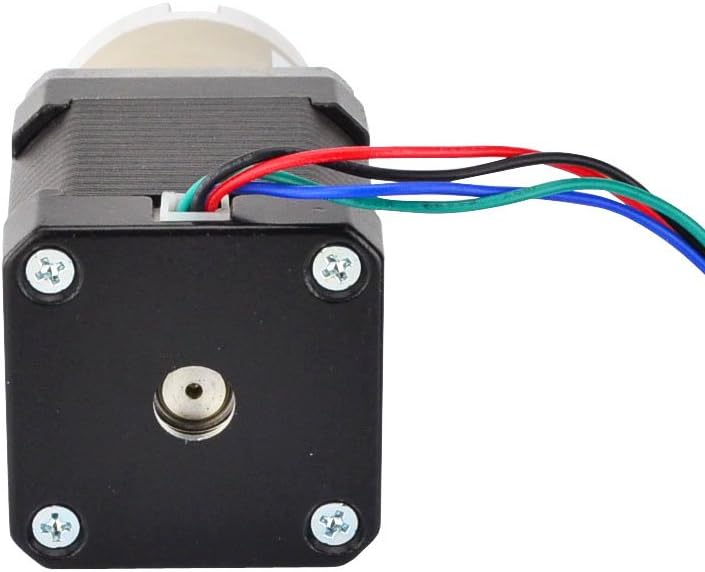

Function of NEMA Gearboxes

A NEMA gearbox works by connecting a motor to mechanical equipment through a standardized interface. It adapts the motor’s output speed and torque to the requirements of the equipment, ensuring optimal performance. The gearbox contains gears that transmit power from the motor’s input shaft to the output shaft, adjusting the rotational speed and direction as needed. NEMA gearboxes come in various sizes and configurations to match specific motor and equipment combinations. They play a crucial role in power transmission, enhancing efficiency and reliability in industrial applications.

editor by CX 2024-03-27

by

Tags:

Leave a Reply