Product Description

Product Description

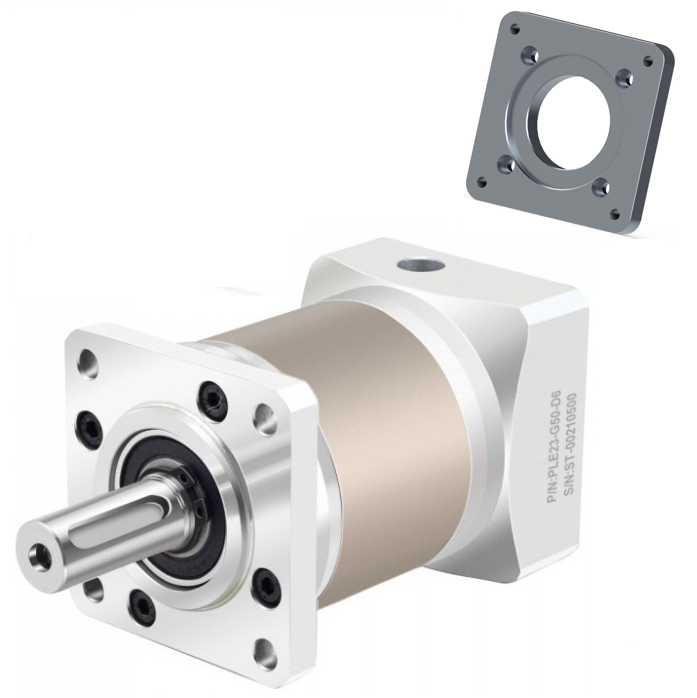

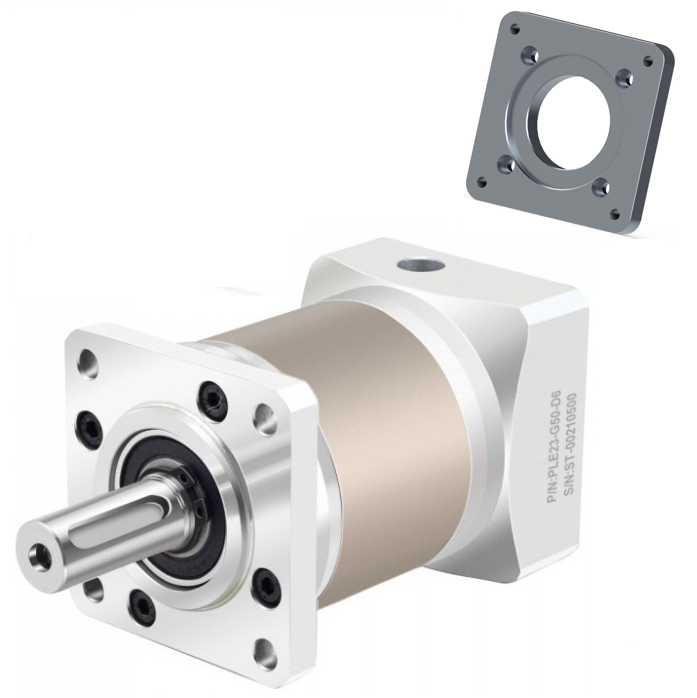

Helical Gear Motor Box PAB 42mm Speed Reducer High Speed Small Planetary Gearbox

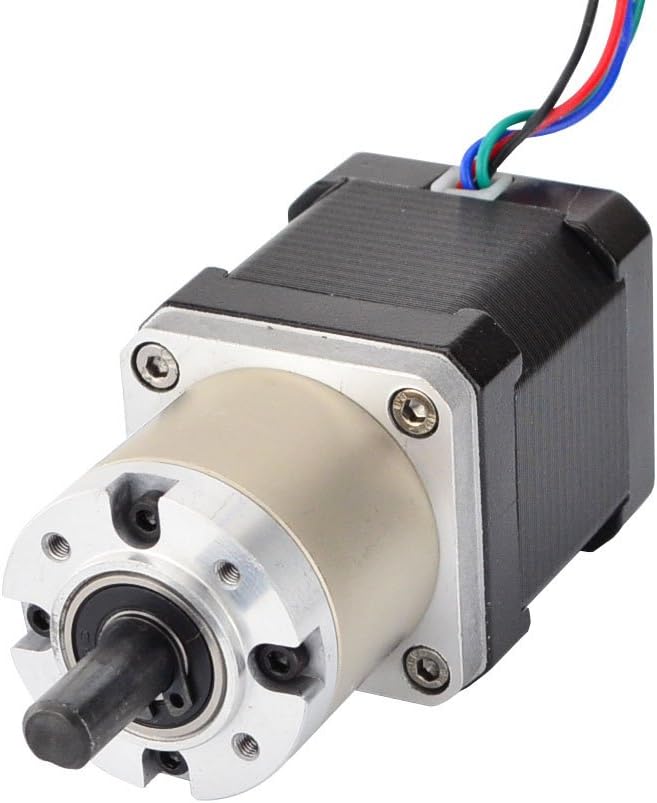

3F PAB series high precision planetary gearbox adopts the integrated design of planet carrier and output shaft to ensure the maximum torque stiffness and stability. Several backlash types can be chosen depends on customers’ needs: Micro precision backlash (P0), precision backlash (P1) and standard backlash (P2) are available. Thanks to the high cost performance of 3F PAB series planetary gearbox, it is widely used in motion control industries for servo application. 3F PAB precision gearboxes are featured with high torque and the input diameter D4 can be up to φ255mm, which can greatly meet the customer needs. Single-stage planetary gearboxes and two-stage gearboxes are available:

.One-stage ratio : 3, 4, 5, 6, 7, 8, 9, 10

.Two-stage ratio: 12, 15, 20, 25, 30, 35, 40, 50, 60, 70, 80, 90, 100

.Note: Three-stage technical data are not available in 3F catalogue. If needed, please contact our salesmen.

Overview of PAB Planetary Reducer

* The minimum backlash can reach to 0-3 arcmin.

* With the advantages of high High torque and high strength.

* It can be applied for any servo motors and stepper motor.

* The positioning time of starting and stoppingis shorter.

* High rigidity and high motor rotor inertia.

* Due to the miniaturization of motor power, it can achieve the stability of inertia load and small vibration.

Product Parameters

| Product type | PLS60 | PLS90 | PLS115 | PLS142 | Reduction rqatio | Number of stage | |

|

Rated output torque |

N.M | 30 | 75 | 150 | 400 | 3 | 1 |

| 40 | 100 | 200 | 560 | 4 | |||

| 50 | 110 | 210 | 700 | 5 | |||

| 37 | 62 | 148 | 450 | 8 | |||

| 27 | 45 | 125 | 305 | 10 | |||

| 77 | 120 | 260 | 910 | 12 | 2 | ||

| 68 | 110 | 210 | 780 | 15 | |||

| 77 | 120 | 260 | 910 | 16 | |||

| 77 | 110 | 260 | 910 | 20 | |||

| 68 | 110 | 210 | 780 | 25 | |||

| 77 | 120 | 260 | 910 | 32 | |||

| 68 | 110 | 210 | 780 | 40 | |||

| 37 | 62 | 148 | 450 | 64 | |||

| 27 | 45 | 125 | 305 | 100 | |||

| Life | Hour | 30,000 | |||||

| Instant stop torque | N.M | Two times of rated output torque | |||||

| Product type | PLS60 | PLS90 | PLS115 | PLS142 | Number of stage | ||

| max radial torque | 3000 | 3900 | 4300 | 8200 | N | ||

| max axial torque | 6000 | 9000 | 12000 | 19000 | N | ||

| Fullload efficiency | 98 | % | 1 | ||||

| 95 | 2 | ||||||

| weight | 3.0 | 4.3 | 9.0 | 15.4 | kg | 1 | |

| 3.8 | 5.7 | 11.6 | 18.5 | 2 | |||

| operating temperature | -25ºC~+90ºC | ºC | |||||

| IP | lp65 | ||||||

| Lubirication type | Lifetime lubrication | ||||||

| Mounting type | Any | ||||||

| The max radial and axial torque work in the location of the center of output shaft when the out speed is 100RPM. | |||||||

Detailed Photos

Application

Company Profile

Certifications

Packaging & Shipping

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

Troubleshooting Abnormal Noises in a NEMA Gearbox

If you encounter abnormal noises in a NEMA gearbox, first check for proper lubrication, inspect for damaged or worn components, listen for specific sounds like grinding or clicking to identify potential issues, ensure proper alignment and mounting, and refer to the manufacturer’s troubleshooting guide. If the issue persists, consult a professional technician to diagnose and address the problem.

Common Problems Associated with NEMA Gearboxes

Common problems with NEMA gearboxes include overheating due to inadequate lubrication or excessive loads, leaks from worn seals or gaskets, abnormal noises caused by misalignment or damaged gears, and vibration issues due to imbalanced loads. Insufficient maintenance can lead to premature wear and reduced performance. Addressing these problems promptly through proper maintenance, regular inspections, and addressing issues as they arise can help prevent major damage and extend the gearbox’s lifespan.

Key Features of NEMA Gearboxes

NEMA gearboxes feature a standardized mounting interface that ensures compatibility with NEMA motors. They are designed to provide efficient power transmission, torque multiplication, and speed reduction. These gearboxes are constructed from durable materials, such as cast iron or aluminum, to withstand varying loads and conditions. They often include precision-machined gears for smooth operation and reduced noise. NEMA gearboxes come in various gear ratios to accommodate different speed and torque requirements. They also offer options for different mounting orientations and motor flange sizes. These features collectively make NEMA gearboxes versatile and suitable for a wide range of industrial applications.

editor by CX 2024-03-28

by

Tags:

Leave a Reply