Product Description

SC Transmission Nema Worm Gear Reducer

Product Description

Aluminum Worm Gear Reducers

Flexible, reliable, and lightweight speed reduction

When your application requires a lightweight speed reducer, SC Transmission’s aluminum right angle NMRV Series worm gear reducers are a durable, reliable, and highly compatible option. Features include a hardened worm shaft for increased durability, 2 bearings on all input and output shafts for reliable performance, and multiple mounting holes for all angle mounts.

A wide variety of NEMA input flange and hollow output bore sizes will ensure compatibility with many applications.

Specifications:

• Housing: One-piece cast aluminum alloy

• Input Compatibility: 56C, 145TC, 182/4TC

• Center Distances: 30 – 90 mm

• Speed Ratio: 7.5:1 – 100:1

Product Features

• 7.5:1 – 100:1 ratios • 30 mm – 90 mm center distances

• One-piece aluminum alloy housing for lightweight strength

• Hardened worm shaft for increased durability

• Two bearings on input and output shafts

• Sizes 75 and 90 have tapered roller bearings on the output shaft

• NEMA motor input flanges • All units filled with synthetic oil for an M1 position mounting

• Adjust oil level for alternative mounting positions

• Double lip oil seals prevent leakage

• Multiple mounting holes for all angle mounts

• Powder coat paint plan on external housing to resist corrosion

• Hollow output bores with plug-in output shafts

• 1 year warranty

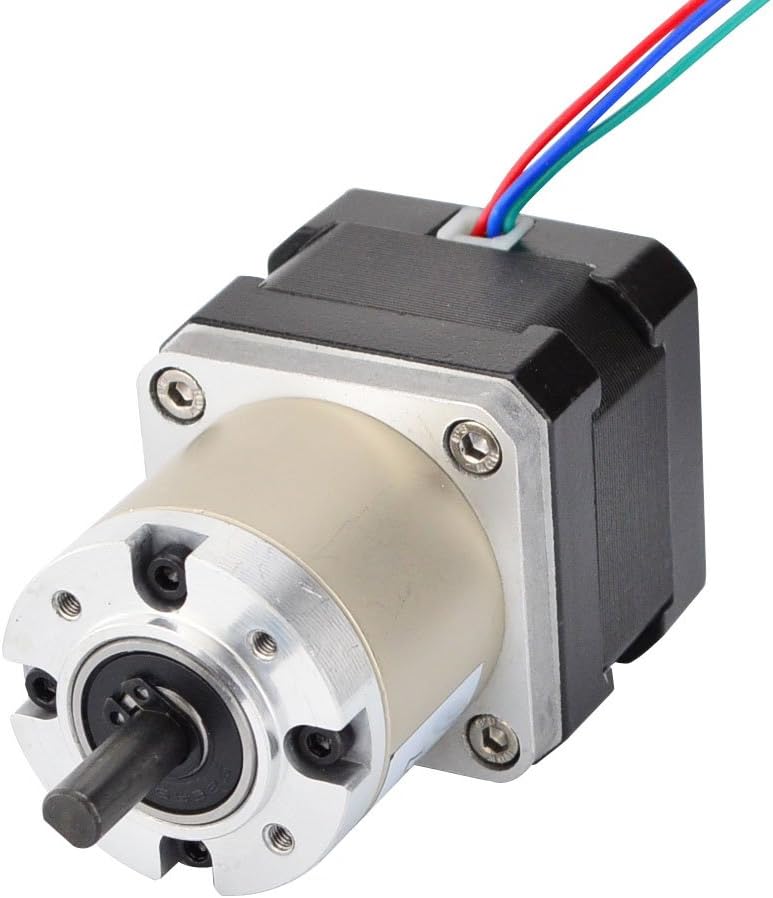

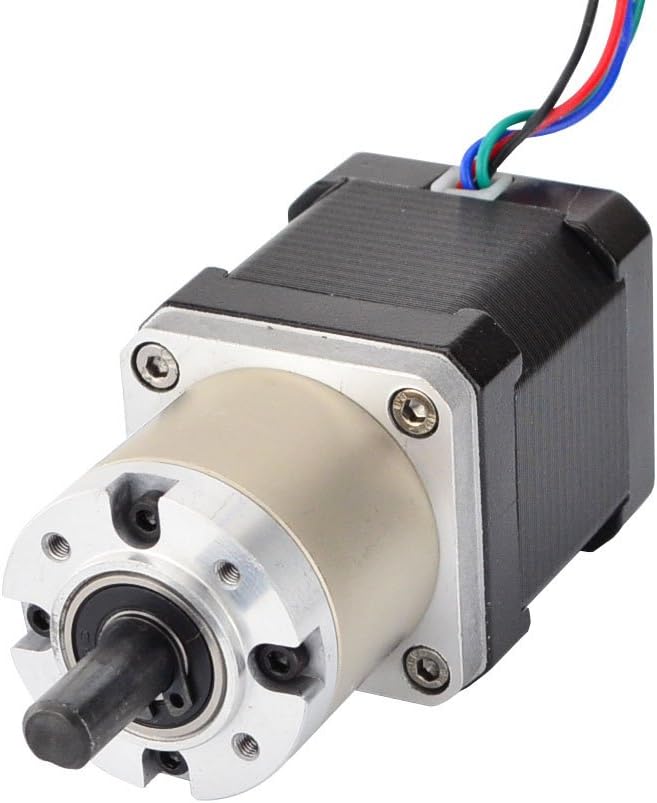

Detailed Photos

Company Profile

FAQ

Shipping

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery, Agricultural Machinery |

|---|---|

| Gear Shape: | Bevel Gear |

| Type: | Worm Reducer |

| Output Torque: | 2.6n.M-1195n.M |

| Input: | Flange or Shaft |

| Input Power: | 0.1-25.8kw |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Calculating Torque Requirements for a NEMA Gearbox

To calculate torque requirements for a NEMA gearbox, you need to consider factors like load type, speed, and efficiency. Use the formula: Torque (Nm) = (Power (W) × 1000) / (Speed (RPM) × Efficiency). Determine the required power and speed, and account for efficiency losses. Ensure that the calculated torque is within the gearbox’s rated torque capacity. It’s essential to factor in safety margins and dynamic loads for accurate results.

Common Problems Associated with NEMA Gearboxes

Common problems with NEMA gearboxes include overheating due to inadequate lubrication or excessive loads, leaks from worn seals or gaskets, abnormal noises caused by misalignment or damaged gears, and vibration issues due to imbalanced loads. Insufficient maintenance can lead to premature wear and reduced performance. Addressing these problems promptly through proper maintenance, regular inspections, and addressing issues as they arise can help prevent major damage and extend the gearbox’s lifespan.

Choosing the Right Size NEMA Gearbox

When selecting a NEMA gearbox size for your application, consider factors such as the required torque, input speed, and output speed. Calculate the torque by multiplying the load’s force by the distance from the axis of rotation. Determine the input speed (motor speed) and desired output speed. Choose a gearbox with a gear ratio that matches your speed reduction or multiplication needs. Check the gearbox’s torque and speed ratings to ensure they align with your requirements. Consider the service factor, which accounts for the application’s operating conditions. You may need to consult gearbox manufacturer catalogs and technical support to find the optimal size for your specific application.

editor by CX 2024-02-29

by

Tags:

Leave a Reply