Product Description

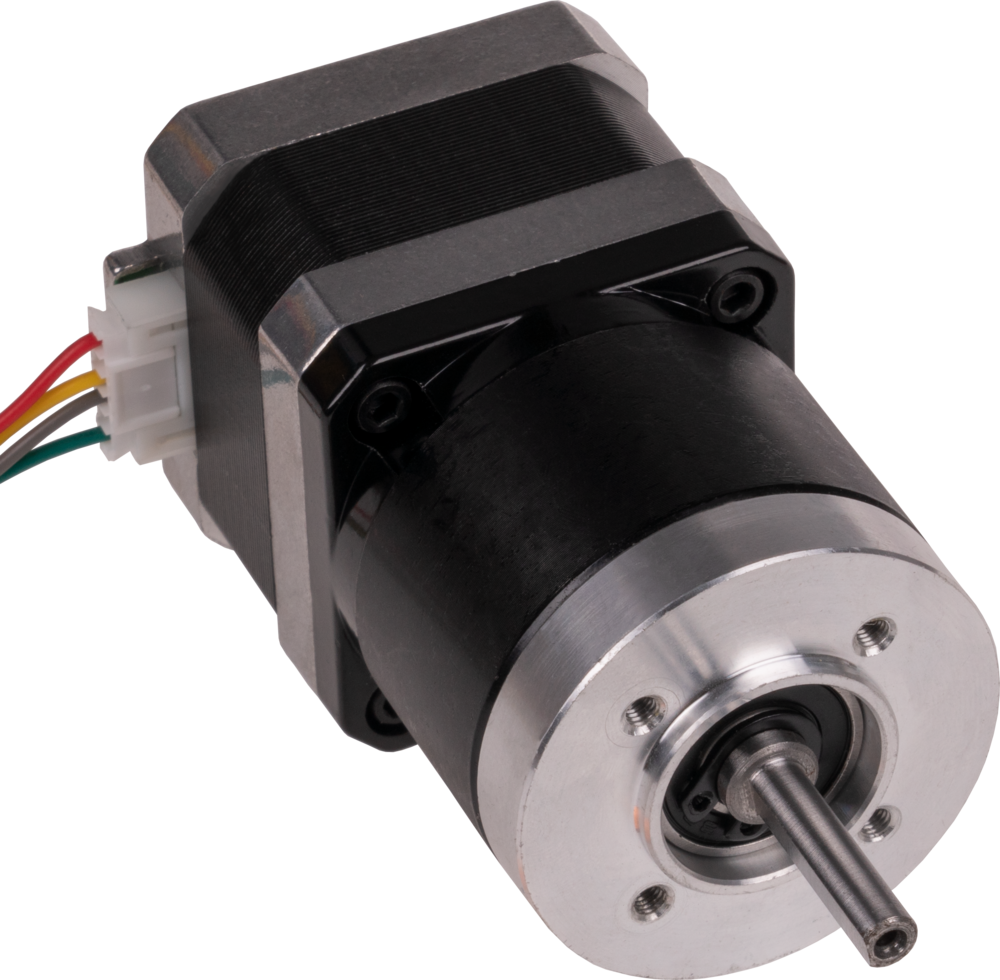

| Product name | Precision Planetary Reducer |

| Model No. | AB42-AB220 |

| Layout form | Planetary structure |

| Speed ratio | 3-512 |

| Output torque | 20-1500N.M |

| Power | 50W~30KW |

| Input speed | 0~4000RPM |

| Output speed | 0~1300RPM |

| Output type | Shaft type |

| Installation | Flange mounting |

Product Description

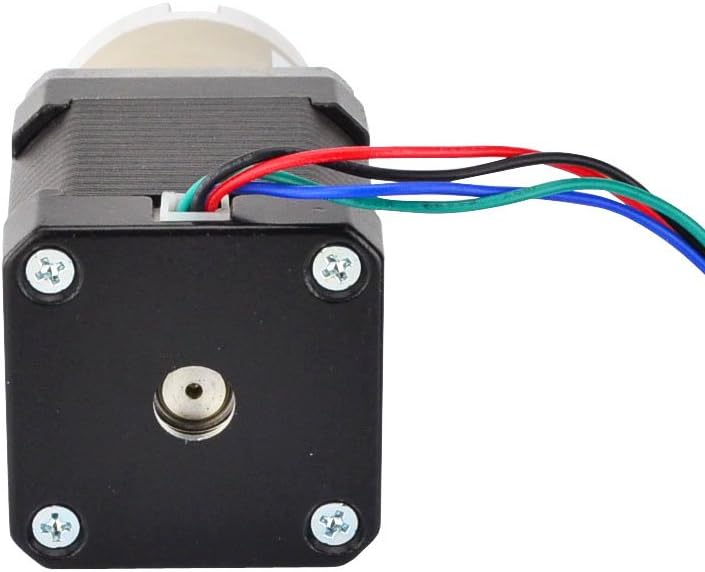

Precision planetary gear reducer is another name for planetary gear reducer in the industry. Its main transmission structure is planetary gear, sun gear and inner gear ring.

Compared with other gear reducers, precision planetary gear reducers have the characteristics of high rigidity, high precision (single stage can achieve less than 1 point), high transmission efficiency (single stage can achieve 97% – 98%), high torque/volume ratio, lifelong maintenance-free, etc. Most of them are installed on stepper motor and servo motor to reduce speed, improve torque and match inertia.

Company Profile

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Hardness: | Hardened Tooth Surface |

|---|---|

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Planetary |

| Step: | Single-Step |

| Type: | Gear Reducer |

| Samples: |

US$ 100/Piece

1 Piece(Min.Order) | |

|---|

Cost of a NEMA Gearbox

The cost of a NEMA gearbox varies widely based on factors like size, type, brand, and features. Smaller, less complex models might start around $100, while larger and more specialized units can range from hundreds to thousands of dollars. Customization, additional accessories, and quality can also influence the price. It’s advisable to request quotes from suppliers or manufacturers for accurate pricing information.

Maintaining and Servicing a NEMA Gearbox

Maintaining and servicing a NEMA gearbox involves regular inspections, proper lubrication, and addressing any issues promptly. Follow the manufacturer’s maintenance schedule and guidelines. Keep the gearbox clean and free from debris, and check for any leaks or unusual noises. Lubricate according to specifications with the recommended lubricant. Replace worn or damaged parts, such as seals or bearings, as needed. Regularly monitor temperature and vibration levels. Proper maintenance can prolong the gearbox’s life and prevent costly breakdowns.

Function of NEMA Gearboxes

A NEMA gearbox works by connecting a motor to mechanical equipment through a standardized interface. It adapts the motor’s output speed and torque to the requirements of the equipment, ensuring optimal performance. The gearbox contains gears that transmit power from the motor’s input shaft to the output shaft, adjusting the rotational speed and direction as needed. NEMA gearboxes come in various sizes and configurations to match specific motor and equipment combinations. They play a crucial role in power transmission, enhancing efficiency and reliability in industrial applications.

editor by CX 2024-03-29

by

Tags:

Leave a Reply